Natural Formation of Asbestos

Asbestos is a naturally occurring mineral that forms deep within the Earth’s crust. It develops over millions of years through geological processes involving heat and pressure. These minerals are part of the silicate family and are known for their fibrous structure. What makes asbestos unique is its combination of strength, flexibility, and resistance to heat and chemicals. This is why it became so widely used in various industries. The fibers are typically found in rock formations, and they can be mined from deposits located around the world.

Historical Mining Practices

Mining asbestos dates back thousands of years. Ancient civilizations, like the Romans, recognized its unique properties and even used it in everyday items. For example, asbestos fibers were woven into cloth-like materials for tablecloths and napkins. During the Industrial Revolution, asbestos mining expanded rapidly to meet the growing demand for industrial applications. Early mining methods were labor-intensive and often dangerous, exposing workers to the harmful fibers without any protective measures. This lack of awareness about the health risks led to widespread exposure, a legacy that continues to affect people today.

Global Distribution of Asbestos Deposits

Asbestos deposits are found on nearly every continent. Major sources include countries like Russia, China, Brazil, and Canada, which have historically been top producers. These deposits are typically located in areas with significant geological activity, such as mountain ranges. The global distribution of asbestos has made it readily available for industrial use, but it has also contributed to its controversial legacy. Understanding where asbestos comes from is essential for grasping its impact on both industry and public health.

Industrial Applications of Asbestos

Common Uses in Construction

Asbestos has long been a go-to material in the construction industry due to its strength and resistance to heat. Builders used it in everything from cement to roofing shingles, as well as in insulation materials. These applications were especially common before its health risks were widely understood. Its durability made it ideal for structures that needed to withstand harsh conditions, but today, its use has significantly declined.

Role in Automotive Manufacturing

The automotive industry also relied heavily on asbestos, particularly in components like brake pads, clutches, and gaskets. These parts needed to handle high levels of heat and friction, and asbestos fit the bill perfectly. Factory workers dealing with these materials were often exposed to dangerous fibers, raising concerns about workplace safety. For instance, factory workers frequently encountered asbestos while handling insulation for pipes and machinery components.

Applications in Fireproofing and Insulation

One of the most well-known uses of asbestos was in fireproofing. It was mixed into sprays and coatings to protect buildings and equipment from fire damage. Additionally, it served as an insulator for pipes, boilers, and electrical systems. While effective, these uses came with severe health risks, which have led to stricter regulations and the search for safer alternatives.

Health Risks Associated with Asbestos Exposure

Respiratory Diseases Linked to Asbestos

Exposure to asbestos fibers can lead to several serious respiratory conditions. When inhaled, these tiny fibers lodge in the lungs, causing irritation and long-term damage. One of the most well-known conditions is asbestosis, a chronic lung disease marked by scarring of lung tissue, which makes breathing increasingly difficult over time. Other conditions include pleural plaques and pleural thickening, which may not always cause symptoms but indicate prior exposure. Additionally, asbestos exposure can contribute to benign lung diseases such as chronic obstructive pulmonary disease (COPD) and fluid buildup in the lungs, known as effusions.

Long-Term Effects on Human Health

The long-term health effects of asbestos exposure are severe and often irreversible. Many individuals develop mesothelioma, a rare and aggressive cancer affecting the lining of the lungs or abdomen, decades after their initial exposure. Lung cancer is another significant risk, particularly for individuals who smoke. The latency period for these diseases can span 20 to 50 years, meaning symptoms may not appear until it’s too late for effective treatment. This delayed onset makes early detection and prevention essential.

Regulatory Guidelines for Exposure

To minimize health risks, strict guidelines govern asbestos exposure in workplaces and public environments. Agencies like OSHA and the EPA have established permissible exposure limits (PELs) to protect workers in industries where asbestos is still present. These regulations require employers to monitor air quality, provide protective gear, and conduct regular health screenings for employees. Adhering to these guidelines is critical for reducing the risk of asbestos-related illnesses and ensuring safer working conditions.

Regulations Governing Asbestos Use

International Bans and Restrictions

Asbestos use has been heavily regulated worldwide due to its serious health risks. Many countries have implemented outright bans, while others have imposed strict limitations. For example, the European Union has prohibited all asbestos-related activities since 2005. Meanwhile, some nations still allow controlled use of certain types, such as chrysotile asbestos. Global efforts aim to reduce exposure and minimize harm, but enforcement varies significantly from one region to another.

Key Legislation in the United States

In the United States, there’s a patchwork of laws governing asbestos. The Clean Air Act and the Toxic Substances Control Act (TSCA) are two major frameworks. Recently, in March 2024, the EPA introduced a ban on ongoing uses of chrysotile asbestos to protect public health from diseases like lung cancer and mesothelioma. This EPA ban reflects a growing commitment to reducing asbestos exposure nationwide. However, older buildings still pose challenges, as many contain asbestos materials that predate these regulations.

Compliance Requirements for Industries

Industries that historically relied on asbestos must now adhere to stringent guidelines. These include:

- Conducting regular inspections to identify asbestos-containing materials.

- Implementing safety measures to prevent worker exposure.

- Properly labeling and managing asbestos waste.

The EPA and OSHA oversee these rules, ensuring businesses follow protocols. For a detailed overview of existing laws, refer to this comprehensive listing of asbestos regulations. Non-compliance can lead to hefty fines and legal repercussions, emphasizing the need for vigilance.

Asbestos in Residential and Commercial Buildings

Identifying Asbestos-Containing Materials

Asbestos was widely used in older buildings due to its heat resistance and durability. Common materials that may contain asbestos include ceiling tiles, insulation, floor tiles, and even certain types of roofing. Recognizing these materials is critical for maintaining safety. Homeowners and building managers should consult professionals for testing if they suspect asbestos is present.

Risks in Renovation and Demolition

Renovation and demolition activities can disturb asbestos fibers, releasing them into the air. This poses a significant health risk to workers and occupants. To minimize exposure, renovations should follow strict safety protocols, including the use of protective equipment and containment measures. Contractors must comply with EPA’s air toxics regulation for asbestos to reduce fiber release during handling.

Safe Management Practices

Managing asbestos in buildings requires a proactive approach. Key steps include:

- Conducting regular inspections to identify potential hazards.

- Sealing or encapsulating asbestos-containing materials to prevent fiber release.

- Hiring licensed abatement professionals for removal when necessary.

By adhering to these practices, property owners can ensure a safer environment for everyone.

The Process of Asbestos Abatement

Inspection and Risk Assessment

Before any action is taken, a thorough inspection is conducted to determine the presence and extent of asbestos-containing materials (ACMs). Trained professionals use specialized tools to assess the risk these materials pose to occupants. Identifying asbestos accurately is critical to prevent unnecessary exposure. Once the inspection is complete, a risk assessment is carried out, outlining the severity of the hazard and recommending the next steps.

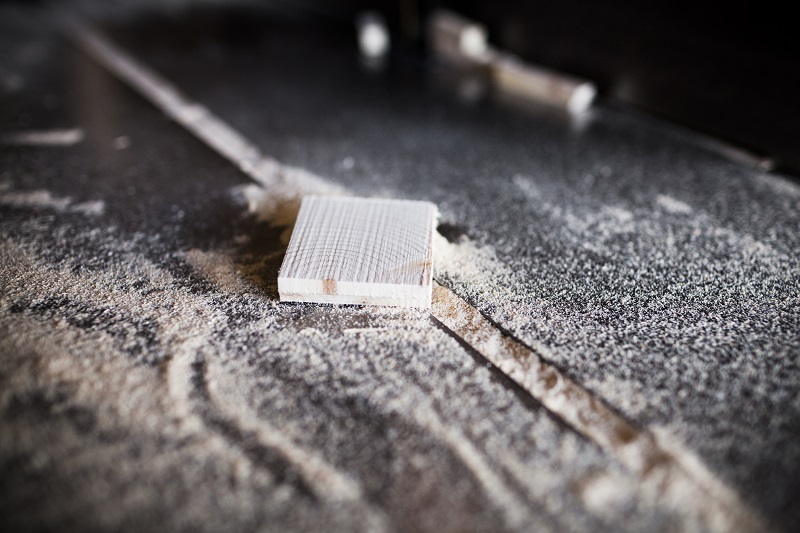

Removal and Containment Procedures

The removal of asbestos is a meticulous process that requires adherence to strict safety protocols. The area is sealed off to prevent fibers from spreading, and workers wear protective gear, including respirators and disposable suits. The ACMs are carefully wetted to minimize airborne particles during removal. Asbestos abatement contractors are responsible for handling this step, ensuring the material is safely extracted and contained in approved bags or containers.

Disposal of Asbestos Waste

After removal, the asbestos waste must be transported to designated disposal sites. The material is double-bagged and labeled as hazardous waste to comply with legal requirements. During transport, precautions are taken to prevent contamination of the environment. Proper disposal is essential, as asbestos cannot be destroyed but must be securely buried to avoid future risks.

Environmental Impact of Asbestos Disposal

Contamination of Soil and Water

Improper disposal of asbestos waste can lead to serious contamination of both soil and water sources. When asbestos fibers are not contained correctly, they can seep into the ground, posing risks to nearby ecosystems. Over time, these fibers may find their way into water supplies, affecting both human and animal populations. Addressing this requires strict disposal protocols to prevent the spread of harmful particles into the environment. Environmental asbestos exposure often stems from such mishandling, highlighting the importance of regulated practices.

Challenges in Safe Disposal

Disposing of asbestos safely is no small task. First, asbestos materials must be carefully identified and isolated. Then, they are typically transported to specialized landfills equipped to handle hazardous waste. However, these facilities are not always accessible, and the high costs associated with transport and disposal can discourage compliance. Additionally, there is the ongoing issue of illegal dumping, which exacerbates environmental contamination and presents enforcement challenges for authorities.

Innovative Recycling Techniques

In recent years, new methods for recycling asbestos have emerged, offering some hope for reducing its environmental footprint. Technologies like thermal deactivation and chemical treatments aim to neutralize the harmful properties of asbestos fibers, converting them into harmless substances. While these methods are promising, they are still in the early stages of adoption and often require significant investment. As these techniques evolve, they could become a more sustainable alternative to traditional disposal methods.

Technological Advances in Asbestos Detection

Modern Testing Methods

Detecting asbestos has come a long way from traditional methods. Today, Transmission Electron Microscopy (TEM) is considered the gold standard in asbestos testing. This advanced technique uses electron beams to deliver precise analysis, making it possible to identify even the smallest asbestos fibers with incredible accuracy. TEM’s ability to provide detailed imaging has made it indispensable for laboratories and industries dealing with asbestos risk. Other methods, like Polarized Light Microscopy (PLM), are still in use but are often supplemented by TEM for more reliable results. These advancements are helping ensure safer environments by improving detection capabilities.

Role of AI in Risk Assessment

Artificial Intelligence (AI) is starting to play a significant role in asbestos detection and risk assessment. AI-powered software can analyze patterns in data collected from testing methods like TEM or PLM, identifying potential risks faster and with less human error. For example, machine learning algorithms can process large datasets to predict areas of high asbestos contamination. This not only speeds up the inspection process but also helps prioritize areas that need urgent attention. The integration of AI is shaping a future where asbestos risk management becomes more efficient and less labor-intensive.

Portable Detection Devices

In recent years, portable detection devices have emerged as a game-changer for on-site asbestos testing. These devices, often equipped with advanced sensors, allow for quick and preliminary identification of asbestos-containing materials. While they may not replace laboratory-based methods like TEM, they provide a convenient first step in assessing potential risks. Portable devices are particularly useful in construction and demolition sites, where immediate decisions are often required. Their ease of use and growing accuracy make them an essential tool in modern asbestos management.

The Future of Asbestos Alternatives

Development of Safer Materials

The shift away from asbestos has driven innovation in creating safer materials that can replicate its properties without the health risks. For example, Thermoacoustic (TAC) roofing materials are emerging as a promising substitute. These materials not only provide durability and insulation but also significantly cut down emissions, reducing environmental impact. Researchers are also exploring bio-based fibers and advanced polymers as potential replacements. The goal is to ensure safety without compromising performance.

Economic Implications of Substitutes

Switching to asbestos alternatives involves a mix of costs and benefits. On the one hand, industries might face higher production costs initially due to the development and adoption of new materials. On the other hand, the long-term savings from avoiding asbestos-related health claims and lawsuits are substantial. Additionally, the demand for safer alternatives is creating new market opportunities, driving competition and innovation. In the end, the economic shift leans toward sustainability and public safety.

Adoption in Various Industries

Industries that once relied heavily on asbestos are now exploring alternatives tailored to their needs. Construction, for instance, is shifting towards fiber-reinforced materials and safer insulation products. Similarly, automotive manufacturing is adopting non-asbestos brake pads and gaskets. The push for a worldwide ban on asbestos has further accelerated the adoption of these alternatives. As more sectors embrace these changes, the transition to a safer, asbestos-free future becomes more achievable.

Public Awareness and Education on Asbestos

Community Outreach Programs

Raising awareness about the dangers of asbestos starts with community outreach. Local organizations and advocacy groups often host informational sessions to educate the public on how to identify asbestos-containing materials and the associated health risks. These events are crucial in reaching underserved areas where information may be limited. Collaborating with schools, libraries, and public health centers ensures a wider reach. For instance, groups like ADAO have been instrumental in uniting voices of victims and spreading knowledge across communities.

Educational Campaigns for Workers

Workers in industries like construction, automotive, and insulation are at higher risk of asbestos exposure. Tailored educational campaigns help these individuals understand workplace hazards and safety protocols. These campaigns often include:

- Clear instructions on protective gear usage.

- Guidance on recognizing asbestos-containing materials in their work environment.

- Steps to follow if exposure occurs, such as reporting to supervisors and seeking medical advice.

Such efforts not only protect workers but also reduce the risk of secondary exposure to their families.

Resources for Homeowners

Many homeowners are unaware that older properties may contain asbestos in roofing, insulation, or flooring. Providing accessible resources, such as brochures or hotline numbers, empowers them to take informed actions. Homeowners should:

- Learn how to spot potential asbestos-containing materials.

- Avoid disturbing areas suspected to contain asbestos.

- Consult professionals for inspections and abatement services.

By equipping the public with knowledge, these initiatives reduce the likelihood of accidental exposure and promote safer living environments.

Legal and Financial Implications of Asbestos Use

Litigation and Compensation Cases

Legal battles surrounding asbestos have been a significant issue for decades. Thousands of lawsuits have been filed by individuals suffering from asbestos-related illnesses, often targeting manufacturers, employers, and property owners. These cases usually claim negligence in protecting workers and the public from exposure. The financial toll on companies has been massive, with some forced into bankruptcy due to overwhelming compensation payouts. Trust funds have been established to handle claims, but the process can be lengthy and emotionally draining for victims.

Insurance Coverage for Asbestos Claims

Insurance policies play a critical role in managing asbestos-related liabilities. Companies often rely on liability insurance to cover legal and compensation costs. However, disputes frequently arise over policy terms, especially regarding whether claims are covered under current or historical policies. This has led to prolonged legal battles between insurers and policyholders. Businesses must carefully review their coverage to ensure they are prepared for potential claims, as gaps in coverage can lead to significant financial strain.

Economic Burden on Affected Industries

Industries linked to asbestos face enormous financial challenges. The costs of litigation, compensation, and regulatory compliance add up quickly. Beyond legal expenses, there are also costs associated with asbestos abatement, employee health monitoring, and public relations efforts to rebuild trust. For some companies, the economic burden is unsustainable, forcing them to shut down or pivot to different markets. Governments and industries are increasingly exploring alternatives to mitigate these financial risks, but the transition is neither quick nor cheap.